direct drive vs belt drive motor

With the motor attaching directly to th e fan wheel the key benefits include. Although the initial cost is high if you keep the washing machine for a couple of years then the extra cost can be recovered easily.

The spindle driving mechanism includes belt drive gear drive direct drive and built-in motor drive.

. Direct drive is definitely better in terms of noise wash performance and power consumption. Belt drives apply greater load on the main shaft of the machine it has a direct effect on the life time of bearings shaft misalignment and as a result oil leakage and more vibrations. An HVAC system with a belt drive fan is slightly different.

For instance a direct drive saw can only cut wood about two inches thick. We discuss positives and negatives for eac. The motor function of the direct drive is different from the belt drive.

This allows for more torque or rotational force which results in less vibration and a steadier rotation. Direct Drive motors are more efficient than belt-drive motors. Direct drive table saws tend to be smaller than belt drive something which may be important if you have little space.

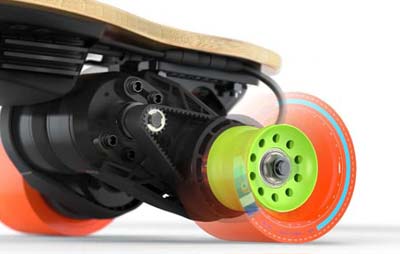

Compared to other electric skateboard motor types such as belt-drive motors hub motors sit at the lower end of the spectrum when it comes to power. Belt-drive motors consist of a pulley system that runs the motor while direct-drive motors use a single motor shaft with all of the power being sent through one winding which leads to more weight being transferred from the motor to the blades. With a belt-driven configuration the movement of the fan is not directly.

For instance the belt will need to be changed and parts need oiled. It is very evident when you compare hub motors to belt-drive motors in acceleration and hill. When compared to belt drive fans which require belts sheaves and bushings direct drive is just plain simpler and.

Reap the benefits of direct drive technology. A belt drive system uses a rubber or cloth belt to connect the motor to the platter. Direct Drive washing machines have lower wash cycles.

Direct Drive motors last longer than belt-drive motors. This kind of pump mounts directly on the motor or engine has few moving parts and is the most cost-effective option. Here a direct drive washer is 38 costlier than a belt-drive model.

Both are created for different audiences. Direct drive pump. A direct drive turntable features quick start-up times slightly more consistent speed and stronger torque.

The second most distinct difference between the two is price. They rotate comparatively easily in both directions. Compared with other driving mechanisms the direct driven spindle design has greater torque power faster and more accurate activation while allowing a larger processing area.

Direct drives requires less space in comparison to belt drives so smaller machines. The direct drive turntable meanwhile features a platter which is directly attached to the players motor. Assuming speed reduction a direct drive low speed motor will have a lower efficiency lower power factor bigger size and higher cost as compared to belt driven higher speed motor.

The direct drive is mainly created for the DJs and designed to work with two turntables while the belt drive doesnt possess such functions. This is mainly due to the 11 power ratio we spoke about earlier. Needing less horsepower to get the job done.

If the pulley loosens it. As you might have guessed the primary difference between a direct drive motor and a belt drive motor is that the former does not utilize a belt. However the bearings and other.

Heating ventilation and air conditioning system with a direct drive blower is when the blower motor is connected directly to the fan. Of course belts themselves have plus. HEIDENHAIN offers the largest direct drive motor range on the market through ETEL.

Belt drive turntables have a few advantages over. There also tends to be less vibration generated by a direct drive motor which will help with the accuracy in your cuts. Some Direct Drive washing machines come with brushless motors to reduce friction and noise.

You have a fan a motor and maybe a coupling. They both are different in how the motor spins and their design differs from each other. A direct drive system connects the motor directly to the platter.

Belt drive washing machines are mostly appreciated for their budget-friendly prices. As direct drive washers are more efficient in their function they remain the top choice for manufacturers in. Ad Industry-recognized low-cogging design.

Belt drive elastic can wear down and it can eventually break. Direct drive fans require fewer parts and thus usually less maintenance. Direct drive pumps are mechanically simpler than belt drive pumps.

The Direct Drive Turntable. Belt-drive turntables by contrast usually take several seconds to get up to speed. As the motor operates and turns the shaft the fan moves accordingly.

In this edition of the QOTW blog the Audio Solutions Team explores the advantages and disadvantages of Direct Drive and Belt Drive turntables. Nonetheless the reason behind the increasing costs is not just direct-drive motor technology. Hub Motors Have Reduced Power.

A direct drive table saw produces less kickback that a belt. Direct Drive Spindle and Belt-Driven Spindle Comparison Categorizations. Check out my gear on Kit.

In summary price and the fact that belt drive motors are not attached directly to the turntable are the two biggest differences. The main difference is how the motor connects to the platter. Due to the simplicity of direct drive pumps the design is more compact which is useful when used in tight areas.

But if you are tight on budget then a belt drive-based washing machine is the only option. However belt drive saws also require more maintenance because of the multiple working parts. Direct-drive tables also will give you a speed control so as a DJ if you want to change the tempo to blend one song into another with two turntables it is pretty easy to do so with the range of speed adjustment available on a direct-drive table.

Hub Vs Belt Which Is Better For Electric Skateboards E Skateboarder

Which Is More Efficient Gear Drive Or Belt Drive Quora

Pin On Magnet Motor Gear Reduction Drive System

Torqueboards Direct Drive Motor Kit Diy Electric Skateboard Electric Skateboard Driving

Torqueboards Direct Drive Motor Kit Diy Electric Skateboard Electric Skateboard Driving

Belt Drives Types Of Belts Fractory

Which Is More Efficient Gear Drive Or Belt Drive Quora

Marathon 48s17d2054 Belt Drive Motor 1 Split Phase Open Drip Proof Resilient Ring Mount Ball B Electric Motor For Bicycle Electric Motor Electric Motor For Car

Belt Drive Motor Kit Diy Electric Skateboard Belt Drive Electric Skateboard

Northstar Belt Driven Generator Head 2 900 Surge Watts 2 600 Rated Watts 5 Hp Required In 2022 Generator Cool Inventions North Star

Century Bf2034b 249 35 Split Phase Belt Drive Motor 1 3 Hp 56z Frame 115 208 230v Ac Voltage 1 725 Nameplate Rpm In 2022 Belt Drive Name Plate Driving

Belt Drives Types Of Belts Fractory

Century H1029 270 13 3 Phase Belt Drive Motor 1 2 Hp 56 Frame 200 230 460v Ac Voltage 1 140 Nameplate Rpm Belt Drive Electric Motor For Bicycle Motor

Hub Vs Belt Which Is Better For Electric Skateboards E Skateboarder

Belt Drive Motor Kit Diy Electric Skateboard Diy Electric Car Electric Skateboard

U S Motors Pd6004 158 19 Capacitor Start Belt Drive Motor 1 3 Hp 48z Frame 115 208 230v Ac Voltage 1 725 Nameplate Rpm Maytag Washer Parts Motor

Dayton 6xh51bg 368 43 Belt Drive Mtr Splitph Odp 1 3hp 1140rpm In 2022 Belt Drive Driving Dayton